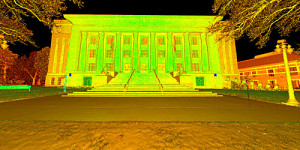

With the rapid growth of technology, people tend to use new methods to expedite their work from small scale to larger-scale projects. Laser scanning is used to collect and measure data on buildings, objects, surfaces, and environments, etc. efficiently.

With the rapid growth of technology, people tend to use new methods to expedite their work from small scale to larger-scale projects. Laser scanning is used to collect and measure data on buildings, objects, surfaces, and environments, etc. efficiently.

Mostly, construction, research, and design industries receive innovative benefits from laser scanning then later developing 3D models for accuracy for their constructions.

Laser scanning is not new technology, but where did it start?

How it all begin?

When people’s needs for recreating accurate data on objects and places, they were continuously finding ways to make their work easier. As a result, 3D scanning technology came to the limelight during the latter part of the 20th century.

The first-ever 3D scanning technology was developed in 1960. Lights, projectors, and cameras were used to support the early scanners. At that time, there were many limitations that consumed a lot of effort and time to properly scan an object.

These older versions were then replaced with modified scanners after 1985. They primarily used white light, shadowing, and lasers to scan surfaces.

Experts began venturing optical technology to create a better model that uses light to capture an object or a surface. The scanner had to be three-dimensional or 3D (data from every angle) and the software-based limitations were occurring.

Cyberware Laboratories of Los Angeles developed an application with their Head Scanner to capture humans predominantly for the animation industry purposes. They had managed to develop a full-body 3D scanner that was named REPLICA launched in 1994. The laser stripe scanning technology (single scan that acquires a large portion of a surface) was evolved with this scanner that was accurate and fast.

Finally, in 1996, the first Reality Capture System was developed that was fast and reliable.

Key benefits of 3D Laser Scanners today:

- They can scan tough surfaces regardless of their material makeup.

- They can withstand changing light conditions and ambient lights well.

- The scanner doesn’t have to touch the object. So the object won’t be distorted or damaged making the scanner produce accurate data.

- Most of them are Portable and cost-effective.

- Their designs are simple.

- User friendly.

- Safe to use.

How does Laser Scanning work?

Laser scanners collect data for project documentation, regardless of the subject. This method is swift, accurate and provides detailed data.

Contemporary scanners have lasers, Global Positioning Systems (GPS), Inertial Measurement Units (IMU) that can measure linear and angular motions of a certain object, sensors, photodetectors (light or other electromagnetic radiation sensors), and receiver electronics.

Say there is a bridge and you need to acquire the measurements (X, Y, and Z, values) of that bridge. Imagine going there with a team and measuring those intricate pieces in person. Daunting, to say the least.

But with a 3D laser scanner, you can acquire these metrics in a matter of minutes. A 3D scanner has an eye-safe, narrow laser beam that can cover a particular area of a surface. This laser beam that is emitted by the scanner can gather millions of sophisticated data on that bridge, roadway, or building without a hassle.

The light waves hit the targeted object and calculate the measurements. Then they come back to the sensor. The time this process takes is known as the time of flight.

Okay. Now you’ve got all the data. What’s next?

The scanned measurements can be carefully collected and saved into a comprehensive point cloud database. These grouped data can be manipulated, viewed, analyzed, and navigated on a laptop or a desktop easily. It is pretty much like a 3D model that is created using a traditional computer-aided design (CAD) system.

High-Definition Surveying (HDS) is beneficial for many things. Interference detection, quantity takeoff, Virtual walkthroughs, interactive 3D models, containment analysis, deformation analysis, critical move plans, demolition plans, and inventory management are just to name a few.

Ways that Laser Scanning is used today:

Laser scanning serves a lot for government-backed high-value projects nowadays. Not to mention privately funded projects like road surveying and national defense projects are also backed up with laser scanning technology.

Most civil engineering related projects are supported by this technology as well. Laser scanning helps any project to accomplish 100% accuracy in less time and effort.

Below are some of the main uses of Laser Scanning today:

1. Study of Towns

Urban topography is a study that is conducted on towns. In this, the towns’ forms, architectural history, geography, layouts, etc. should be accurately determined for town planning.

Urban planners with laser scanners support this critical process by collecting and processing data prior to any development.

Laser scanning also helps with civil surveying, mining, reverse engineering, archaeological projects, etc.

2. Road Surveying and Traffic Construction

Laser scanning can complete road surveying and traffic construction analysis in a matter of hours.

With laser scanning, this is done easier than ever. During road construction, it can reduce the task completion time without stopping the traffic or delaying the construction work.

Laser scanning also reduces the workforce because it’s fully automated except for tasks such as handling equipment, data collection, analysis, and CAD model development that require people.

3. Spatial Scanning

In Spatial Scanning, errors and time wastage aren’t acceptable. Laser scanning eliminates both of these problems.

Needless to say, laser scanning largely supports improving the process of planning as well.

Because of the efficiency and the accuracy that is provided by laser scanning during spatial scanning, researchers are further inspired to use it for surveying, mobile mapping, scanning buildings and interiors as well.

Conclusion

As previously mentioned, 3D laser scanning technology has been around for quite some time. With the evolution of technology, it has been developed in a way that is incredibly useful for all the people who need to make their work a little easier.

3D laser scanning saves money, time, and effort that ultimately will make a tremendous positive impact on your work.

If you have any questions involving laser scanning or would like more information regarding your next large construction project, please reach out to us HERE today. We look forward to working with you!